The Ferdinand Berthoud FB 1R.6-1 Explained

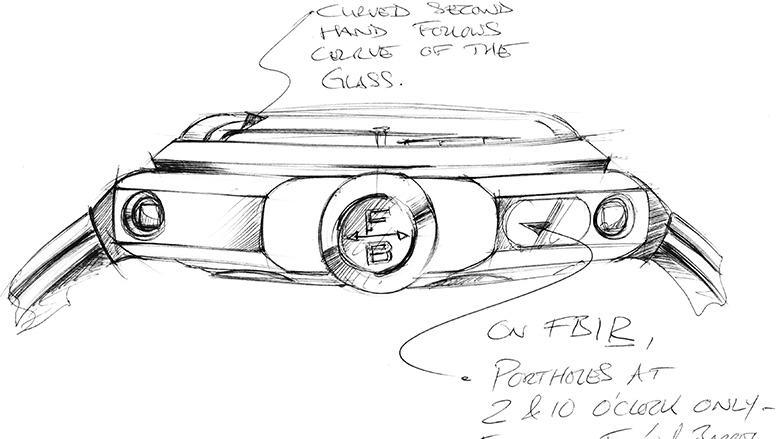

With its original regulator-type display and its ultra-resistant carburised stainless steel case, the Chronomètre FB-1R.6-1 enriches the Chronométrie Ferdinand Berthoud collection. This new presentation radically transforms an exceptional timepiece whose complications, together with the quality of its construction and production, remain true to their underlying philosophy. Its FB-T.FC.R tourbillon caliber with fusee-and-chain transmission can be admired through a sapphire crystal caseback and two lateral portholes, offering a unique view inside this outstanding chronometer.

Like the previous editions of the Chronomètre FB 1, its movement is equipped with horological complications inspired by the scientific instruments represented by Ferdinand Berthoud’s marine chronometers. The appearance of the Chronomètre Ferdinand Berthoud FB 1R.7-1 takes its cues from the Marine Chronometer No. 7. The philosophy upheld by Chronométrie Ferdinand Berthoud involves transposing into contemporary language the pursuit of excellence undertaken by the master horologist appointed Clockmaker to the French King and Navy. A rare and unusual-looking timepiece, the Chronomètre Ferdinand Berthoud FB 1R.6-1 is a comprehensive horological work, issued in a 20-piece limited edition intended for discerning and passionate collectors.

A Philosophical Approach: The different versions of the Chronomètre Ferdinand Berthoud FB 1 stem from an innovative horological approach. The design, movement, finishing and everything composing this chronometer with tourbillon and constant force are highly specific and reflect an uncompromising commitment to excellence. Chronométrie Ferdinand Berthoud is driven by the vision of its president, Karl-Friedrich Scheufele. The latter has patiently built up an important collection of objects relating to time measurement within the L.U.CEUM museum in Fleurier, including a number of works by Ferdinand Berthoud.

In paying worthy tribute to this native of the Val-de-Travers, Chronométrie Ferdinand Berthoud has a dedicated team, a specific development process and authentic expertise in a wide range of skills. In the case of the Chronomètre Ferdinand Berthoud FB 1R.6-1, the inspiration stems directly from Ferdinand Berthoud’s research on his Marine Chronometer no. 7. The latter housed a number of solutions that improved the operating principles of its longitude watches. Among them was its display that differed from the usual rules governing regulators – which assign a different place on the dial to the hours, minutes and seconds displays – by the use of a large central seconds hand.

The case features two octagonal-shaped stainless steel side pieces, giving it a characteristic shape including two lateral portholes at 2 and 11 o’clock – providing a chance to admire the chain-and-fusee mechanism in action. These two openings are complemented by a screw-down stainless steel caseback fitted with glare-proofed sapphire crystal enabling observers to appreciate the high-quality finishing lavished on the FB-T.FC-R movement.

The knurled 9mm-diameter stainless steel crown bearing a black ceramic medallion ensures smooth winding of the movement endowed with a 53-hour power reserve.

Exceptional Regulator: The novel construction of the Chronomètre Ferdinand Berthoud IR.6-1 sets it apart from all existing regulator-type displays. Instead of featuring a high-up opening providing a view of the tourbillon and the fourth wheel (driving the seconds) as on previous versions, the Chronomètre Ferdinand Berthoud FB 1R.6-1 has a mostly solid dial. The latter is, in fact, the rear side of the complication plate that provides the regulator-type display.

It is made of nickel silver, vertically satin-brushed by hand and black rhodium-plated. Of the three small apertures, the first serves to show the hours, offset at 2 o’clock and appearing on a glare-proofed sapphire crystal disc bearing transferred Arabic numerals striking a pleasing contrast with a white background. The second opening features an original power-reserve display mechanism, distinguished by a large dial cut-out revealing part of the finely sandblasted and black rhodium-plated mainplate. Located in the center of the finely chamfered, bead-blasted and black rhodium-plated minutes counter, the third aperture displays a hand-engraved “pyramid” motif inspired by an openworked Ferdinand Berthoud astronomical clock belonging to the L.U.CEUM collection. Meanwhile, the seconds appear around the rim of the dial on a flat inner bezel ring made of black rhodium-plated, bead-blasted and chamfered nickel silver.

Finally, the nature and provenance of the Chronomètre Ferdinand Berthoud FB 1R.6-1 can be read off on this large dial, engraved with the inscription “Chronomètre Val-de-Travers Suisse.” More than merely representing a signature or an appellation of origin, it proudly proclaims the model’s identity.

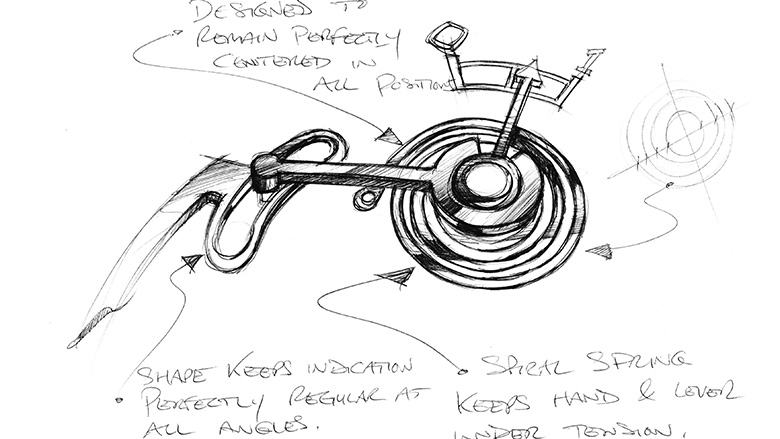

Suspended Mobile Cone Power-Reserve Display and Spiral-Spring: A patent has been filed for the extremely sophisticated power-reserve indication mechanism. Visible through a cut-out in the half-bridge on the caseback side, a truncated cone moves up and down along an arbor connected to the barrel. This suspended cone is topped by a feeler spindle in the form of a mobile arm tipped with a watch jewel. The latter’s position on the cone reflects the barrel’s state of wind.

The feeler spindle, in turn, transmits the quantity of energy accumulated by the mainspring to a set of finely chamfered and rhodium-plated flat levers visible through a cut-out in the regulator plate. Its role is to amplify the displacement of the power-reserve hand. A spiral spring placed at the far end of its travel exercises a force on the base of the power-reserve hand. This spring serves to compensate for the play between the various components of this mechanism and to display the power reserve with peerless precision.

A number of complex mathematical calculations and various tests served to fine-tune the geometry of this spring, made from a nickel-phosphorous alloy in order to guarantee the concentric deployment of the coils in all states of winding and unwinding, and thereby to avoid any unattractive distortion that might also be detrimental to the smooth running of the mechanism. This ingenious device is imbued with the experimental spirit of Ferdinand Berthoud himself, who reveled in exploring solutions resolutely off the beaten track.

A Slender, Finely Structured Movement: The FB-T.FC.R caliber is built according to a unique architectural concept. This hand-wound movement features 18 nickel silver bridges framed by polished titanium pillars surrounding the mechanical organs. This construction is typical of 18th-century marine chronometers. The architectural approach is picked up in the design of all the components, and especially in the symmetrical equilibrium of the movement.

The distinctive nature of the FB-T.FC.R caliber lies in its inverted upside-down barrel and fusee, and particularly in the fact that both elements are suspended, meaning held on only one side. A patent has been filed for this construction which saves precious millimeters. At 9.89mm thick, the movement of the Chronomètre Ferdinand Berthoud FB 1R.6-1 thus remains extremely thin for its category despite the regulator-type display and the new power-reserve indication.

Keeping Things Moving: When the mainspring is combined with a fusee, the barrel drum turns in one direction when the spring is unwinding and in the other when it is winding, hence serving to coil the chain. The movement generally stops while this type of mechanism is being wound. To prevent this, the FB-T.FC.R caliber is equipped with a differential gear based on an original concept and for which patent has also been filed. It enables the balance wheel to continue oscillating during winding and thereby maintain the movement’s precision timekeeping properties.

The winding mechanism is fitted with a pinion featuring cone-shaped toothing. Coupled with a large-diameter knurled crown, it enables smooth movement winding. This gentle motion, which is essential in the case of manual winding, enhances the quality of the day-to-day rapport between the watch and its owner.

Force And Safety Features: As typically found on chain-and-fusee mechanisms, the barrel of Caliber FB-T.FC.R is equipped with a “Maltese Cross” stopwork device. The latter serves to limit the winding turns of the mainspring to around six, so as to use only the most stable portion of this spring. This device also acts as a buffer when the barrel is fully wound. At that point, the mainspring torque exerts a 3 kg force, which is considerable for the chain components measuring just a few millimeters.

To perfect the security of the movement, the engineers at Chronométrie Ferdinand Berthoud have equipped the crown with a dynamometric function serving to avoid any damage to the movement that might be caused by excessive winding.

Tourbillon With Central Seconds: Teamed with the fourth (seconds) wheel and pinion, the tourbillon of Caliber FB-T.FC-R comprises 67 components assembled within a titanium carriage measuring 16.55mm in diameter, and fixed to a perfectly hand-polished and chamfered arrow-shaped steel arch whose tip points towards the space between the barrel and the fusee. To poise the escapement’s unbalance, two 18-karat gold inertia-blocks ensure the uniform spread of the weights of this large-size tourbillon. This tourbillon contributes to earning Caliber FB-T.FC.R its chronometer title awarded by the Swiss Official Chronometer Testing Institute (COSC). One particular characteristic makes the tourbillon extremely distinctive: although it performs one rotation per minute, it does not indicate the seconds, since the Chronomètre Ferdinand Berthoud FB 1R.6-1 is one of the rare tourbillons to have a central sweep-seconds hand. Extremely long, slim and made of gilded bronze, the latter moves with remarkable accuracy and in a remarkable stable manner.

Noble Materials: Within the traditional approach to watchmaking, construction and mechanical structure are inseparable from the choice of materials and the quality of the finishing. In this respect, the movement of the Chronomètre Ferdinand Berthoud FB 1R.6-1 is in a league of its own. The bridges of Caliber FB-T.FC.R are made of untreated nickel silver: a copper, zinc and nickel alloy that is particularly shiny when polished, yet also extremely fragile. Any imperfection is irreparable. Nickel silver is also distinguished by its warm grey color easily recognized by connoisseurs.

It coexists here with steel, a new material in the array of metals used by Chronométrie Ferdinand Berthoud. This is an ultra-resistant carburised steel, based on a high-tech thermos-chemical surface treatment. It consists of diffusing carbon into a steel substrate, thereby increasing the hardness of the alloy without destroying its initial properties. In this instance, it reaches the record figure of 1,200 Vickers, making the Chronomètre Ferdinand Berthoud FB 1R.6-1 exceptionally scratch-resistant. The choice of this type of steel, currently used in the aerospace industry, is a nod to the maritime expeditions achieved using the Marine Chronometers produced by Ferdinand Berthoud in the 18th century and which required the use of extremely sturdy materials.

Meticulous Finishing: The stainless steel arrow-shaped tourbillon bridge is decorated with the utmost care. The upper side is specular-polished, the flanks are straight-grained, the angels are polished, and the underside is circular-grained and smooth-polished. All levels of the titanium tourbillon bridge are entirely chamfered. Some surfaces are polished, others circular satin-brushed, sandblasted or smooth-polished. The lever bridge is completely chamfered and its visible side features a specular-polished finish while its hidden side is straight-grained. The power-reserve cone is mirror-polished.

The two bridges framing the tourbillon of the Chronomètre Ferdinand Berthoud FB 1R.6-1 feature cut-outs. Through one of these apertures, the baseplate has been engraved with the same pyramid pattern as the hours dial, while the other reveals the power-reserve cone in all its splendor. The barrel and fusee are gilded, creating a pleasing contrast with the rough nickel silver and titanium which are omnipresent in the movement. The 790-part stainless steel chain measuring 285mm long is also entirely hand-finished. The sides and studs are satin-brushed and the flat surfaces are polished.

Accurate Workmanship: Whatever the position and function of the components, these finishing operations are entirely done by hand using traditional tools in the workshops of Chronométrie Ferdinand Berthoud. The quality control of this finishing is performed at a far higher degree of magnification than usual, with a 6x loupe. Under such intense scrutiny, no detail, however tiny, goes unnoticed. No error, imperfection or insufficiency is tolerated. Such is the horological excellence cultivated by Chronométrie Ferdinand Berthoud as part of its unfailing commitment to precision for explorers. This respect for watchmaking tradition, expressed in resolutely modern terms through Ferdinand Berthoud chronometers, will remain at the core of future developments from the Maison.